Ich glaube, wenn mich heute jemand fragt, ob ich noch mal meine eigene Uhr herstellen würde, dann müsste ich erst überlegen. Es war ein Mammut-Projekt und ich bin froh darüber, dass mir das zu Anfang nicht bewusst war, denn dann gäbe es die Corazón del Mar vielleicht nicht. Mein Hauptaugenmerk war es, eine absolut hochwertige Uhr zu fertigen. Viele neue Marken möchten meist mit einem günstigen Preis die Kunden zum Kauf animieren und verbauen dann neben preiswerten Materialien auch billige Werke. Mein Ziel war, von Beginn an eine Uhr zu kreieren, die einer Luxusuhr in nichts nachstand, auch wenn es das Gesamtprojekt nicht gerade einfacher werden ließ. Aber mein Uhrmacher und ich sind nun mal absolute Enthusiasten und leidenschaftliche Uhrenliebhaber. Wir konnten also gar nicht anders, sonst hätten wir uns selbst verraten.

Zunächst kam der Gedanke auf, auf möglichst viele, bereits fertige Teile zurückzugreifen, um so die Kosten im Rahmen zu halten, ohne an Qualität einzubüßen. Ich beschaffte mir also Gehäuse, passend für ETA bzw. Sellita-Werke, Zifferblatt, Zeiger etc. und baute mir so einen ersten Prototypen. Nachdem wir viel experimentiert hatten, kamen wir zum Schluss: Ja, sollte realisierbar sein! Mein Wunsch war es, von Anfang an meine Youtube-Community mit einzubinden und so veröffentlichte ich am 24.11.2016 ein Video, in dem ich mein Vorhaben, eine eigene Uhr herzustellen, präsentierte. Die Resonanz war extrem positiv, was mich sehr bestärkte.

Den richtigen Namen für eine Uhrenmarke zu finden, ist nicht einfach. Letztendlich ist ein schöner Name ebenfalls sehr subjektiv, denn auch hier spielt der persönliche Geschmack eine Rolle und über den lässt sich einfach nicht streiten. Deshalb war es uns wichtig, einen Namen zu finden, der uns gefiel. Mein Uhrmacher schlug vor, da wir ja mit dem Saphir auf dem Rotor das „Herz des Meeres“ hatten, den Namen daran anzulehnen. Zunächst dachten wir an „Coeur du Mer“ aber das wäre grammatikalisch falsch gewesen, denn es heißt korrekt „Coeur de la Mer“ und damit klang es zu weiblich. Da ich meine Kindheit und Jugend in Spanien verbracht hatte, übersetzte ich den Namen ins Spanische: „Corazón del Mar“! Das gefiel uns gut und der Name war geboren. Eines war mir bewusst: Es würde keinen Namen geben, der jedem gefällt. Und genau aus diesem Grund war es uns wichtig, dass der Name primär uns selbst gefallen musste, denn wir identifizieren uns mit unserer Marke.

Auch wenn ich am Anfang auf ein vorgegebenes Gehäuse zurückgreifen wollte, so sollte dieses individualisiert werden. Uns kam der Gedanke, die Seitenflanken auszufräsen und ein Inlay z. B. aus Aluminium einzusetzen. Da man Aluminium färben kann, hätte dies einen interessanten, farbenfrohen Effekt ergeben. Da aber Alu mit Stahl reagiert und es zu Ausblühungen kommen kann, wurde diese Option später verworfen.

Generell musste ich mich natürlich mit meinen Ideen nach der Decke strecken, denn ich hatte ja keinerlei Garantie, dass meine Uhr später auch erfolgreich verkauft werden würde. Alle meine Ideen mussten also realisierbar sein, ohne dass ich Haus und Hof verlor. Aus einer revisierten Omega Ploprof hatte ich Zeiger in meiner Schublade. Da mir dieser Zeigerstil sehr gefiel, setzte ich sie in meinem Prototypen ein. Wenn man sich unsere Zeiger bei der Melanocetus heute anschaut, so sieht man, dass dies ein Designelement war, das uns von Anfang an gefallen und auch Einzug in die finale Uhr erhalten hat.

Aber je länger man sich mit einem solchen Projekt befasst, desto mehr Ideen bekommt man und diese werden dann immer ehrgeiziger. So kam es auch, dass wir mit unserem fertig eingekauften Zifferblatt nicht mehr zufrieden waren. Gerade das Zifferblatt ist maßgeblich für den Charakter einer Uhr verantwortlich und wir wollten hier etwas Eigenes entwickeln. Unser entferntes, aber festes Ziel ist es, einmal eine echte Manufaktur zu werden, in der fast alles eigenhändig erzeugt wird. So ging auch der Gedanke für den Zifferblattdruck direkt in Richtung „das machen wir selbst“. Dass zwischen dem enthusiastischen Gedanken und dem ersten, unseren Ansprüchen genügenden Zifferblattdruck eine gewaltige Odyssee lag, das war uns zu diesem Zeitpunkt noch nicht klar.

Ich bin zwar ein erfahrener Designer, aber ein Zifferblatt für eine Uhr hatte ich noch nie entworfen. Es ist etwas anderes, ob man ein Logo oder eine Webseite designt, wo es auf Zehntelmillimeter nicht ankommt oder eben ein Zifferblatt, das auch noch seine technische Funktion erfüllen muss. Das ganze Projekt wurde immer komplexer, nervenaufreibender, anstrengender und jedes Mal, wenn wir dachten, wir gingen schon auf dem Zahnfleisch, kam noch eine Hürde hinzu, die es zu überwinden galt. Natürlich haben wir all dies super gerne in Kauf genommen, denn wo kann man seine Leidenschaft zu Uhren besser ausleben als dabei, die eigene Uhr zu entwickeln?

Mit einem nicht unerheblichen Aufwand war es uns zwischenzeitlich gelungen, unsere Ausfräsungen am Gehäuse vorzunehmen. Wir experimentierten auch mit verschiedensten Materialien für die Inlays. Am Ende wurden es Keramikinlays. Diese haben keinerlei technischen Sinn, sie dienen rein der Optik und sind eine interessante Abwechslung zu den üblichen Standardgehäusen. Allerdings bieten sie durch die Härte der Keramik auch einen nicht unerheblichen Schutz für die Seitenflanken.

Während wir also noch an der Gestaltung des Gehäuses arbeiteten, gingen immer weiter Vorbestellungen für unsere Uhr ein, sodass wir hier eine Größe erreichten, die es uns erlaubte, direkt mit Werksherstellern in Kontakt zu treten. So kam es, dass wir unser Wunschwerk, das Sellita SW200, direkt beziehen konnten. Diese Werke werden von sehr vielen bekannten Luxusmarken als Basiswerke eingesetzt, unter anderem von Hublot. Bei Werken gibt es häufig verschiedene Qualitätsstufen und da wir für unsere Uhr nur das Beste wollten, haben wir hier die höchste Stufe inkl. gebläuter Schrauben gewählt.

Je länger wir mit unserem „Standardgehäuse“ arbeiteten, umso mehr kamen wir an Grenzen. Auch die Stegbreite von 21 mm störte uns extrem. Im Regelfall haben die meisten Uhren Standardbreiten von 20, 22 oder 24 mm. Hier existiert eine breite Auswahl an Bändern auf dem Zubehörmarkt. Bei den Zwischengrößen, wie eben bei 21 mm, ist die Auswahl extrem beschränkt. Wir wollten aber niemanden beschränken.

Auch lehnte sich das Gehäuse vom Design her zu sehr an andere Marken an und war uns nicht eigenständig genug.

Obwohl wir wussten, dass es nicht einfach werden würde, beschlossen wir im Januar 2017 das Projekt endgültig auf komplett eigene Beine zu stellen und gaben bekannt, dass wir unsere eigenen Gehäuse herstellen lassen möchten. Klar war auch, dies würde nicht ohne eine Mindestanzahl an bezahlten Vorbestellungen realisierbar sein, denn wir mussten eine Mindestabnahmemenge von 200 Gehäusen fertigen lassen. Dennoch wollten wir es versuchen und hatten den festen Glauben, dass es funktionieren kann. Manchmal gehört auch ein wenig Glück dazu, denn wir fanden zufällig einen sehr erfahrenen Partner aus der Schweiz, der in den 80er/90er-Jahren für Breitling die Gehäuse hergestellt hatte. Also ein Mann mit unendlich viel Erfahrung. Mit seinem Wissen und seinen Kontakten wollten wir also unsere Gehäuse produzieren lassen, aber es stand und fiel alles mit den Vorbestellungen. An dieser Stelle möchte ich mich noch einmal bei allen Erstbestellern bedanken. Wir hatten ja außer einer großen Fotomontage der Uhr, wie sie denn einmal aussehen sollte, nichts weiter vorzuweisen. Das unendliche Vertrauen, das die über 70 Vorbesteller-Pioniere uns schenkten, war außergewöhnlich. Innerhalb weniger Tage hatten wir bereits die nötige Anzahl an Bestellungen erhalten und wir setzten alles daran, dass die Corazón del Mar MELANOCETUS eine außergewöhnliche und extrem hochwertige Uhr wurde.

6 Monate später war es dann soweit, die ersten Mustergehäuse trafen ein und hatten nicht nur unsere Erwartungen erfüllt, sondern mehr als übertroffen. Der nächste Meilenstein war also erreicht. Allerdings experimentierten wir seit Wochen mit dem Zifferblattdruck. Er wollte einfach nicht unseren hohen Ansprüchen genügen und es vergingen unendlich viele Stunden, bis unser Druckergebnis nicht nur einwandfrei, sondern perfekt war. Nicht nur, dass die Siebe und deren Lochgrößen eine wichtige Rolle spielten, auch die Konsistenz der Farbe war entscheidend. Die Farbe wurde wiederum aus verschiedenen Komponenten angemischt, die nur in der exakt richtigen Mixtur zum gewünschten Ergebnis führte. Mittlerweile hatten wir ein großes Glas randvoll mit fehlgedruckten Zifferblättern, das wir dann liebevoll unser „Glas der Erkenntnis“ nannten. Denn jedes misslungene Blatt offenbarte uns unsere Fehler und half uns ein Stück weiter auf dem Weg zum perfekten Druck.

Später, als wir endlich erfolgreich unsere Blätter gedruckt hatten, ernteten wir beeindruckendes Lob von einem Spezialisten, der jahrelange Erfahrung im Druckbereich hatte, denn er konnte es nicht glauben, dass wir dies alleine geschafft hatten. Leider haben wir diesen Experten ein paar Wochen und viele Nächte zu spät kennengelernt.

Unsere Fertigungstiefe ist ein absolutes Pfund, denn selbst manch größere Marke fertigt kaum etwas selbst. Wir hätten es uns auch einfach machen und die Uhrwerke in der Schweiz bequem bei einem Einschaler zusammenbauen lassen können. Für die, die es nicht wissen, ein Werk wird nicht in eine Uhr eingesetzt, man nennt dies „einschalen“. Das machen sehr viele so und werben dann mit der Bezeichnung „Swiss Made“. Unser Ziel war aber ein echtes „Made in Germany“ und diese Kriterien übererfüllen wir. Wir finishen in Deutschland die Gehäuse, schalen die Werke ein, befüllen manuell die Zeiger mit Super-LumiNova, drucken die Zifferblätter, fertigen die Cabochonperle, fassen die Edelsteine, verzieren den Rotor, trocken die Gehäuse im Vakuum und befüllen diese mit Argon u. v. m.

Ich erlebe es leider häufig, dass sich viele nur oberflächlich mit den technischen Daten einer Uhr auseinandersetzen und dann Äpfel mit Birnen vergleichen. So müssen wir immer den Vergleich mit günstigeren Uhren über uns ergehen lassen, nur weil das gleiche Werk verbaut ist. Stellen wir die Frage einmal anders herum, was macht unsere Uhr so einzigartig und wertvoll?

- Ein vollkommen eigenständiges Design. Sowohl unser Gehäuse, als auch unser Zifferblatt, unsere Lünette etc. wurden alle individuell von mir persönlich designt und sind keine Massenware.

- Die Seiteninlays aus Keramik sind ein optisches Highlight, schützen die Flanken vor Kratzern und sind ein Alleinstellungsmerkmal, das uns viel Geld und Entwicklungszeit gekostet hat.

- Das System mit der Cabochon-Halbperle ist äußerst aufwendig. Die Perlen werden von Hand geschliffen. Das Gehäuse wird im Vakuum getrocknet und anschließend mit Argon geflutet. Jede Uhr ist alleine 24 Stunden in der Trocknung. Alle diese Arbeiten werden in unserer Manufaktur durchgeführt, erfordern Zeit und Fachwissen.

- Der Saphir auf dem Rotor ist nicht nur ein besonders schöner Stein, sondern wird ebenfalls von Hand in unserer Manufaktur gefasst und auf dem Rotor eingelassen.

- Die Zeiger werden von Hand in unserer Manufaktur mit Super-LumiNova gefüllt.

- Die Zifferblätter werden von Hand in unserer Manufaktur bedruckt!

- Jede Uhr wird erst nach Bestelleingang, individuell für den jeweiligen Kunden, von Hand gebaut! Das ist nahezu einzigartig! Bei uns liegen Uhren nicht monatelang fertig im Lager!

Wenn man das alles berücksichtigt, ist unsere Melanocetus ab 1250 € ein absolutes Schnäppchen!

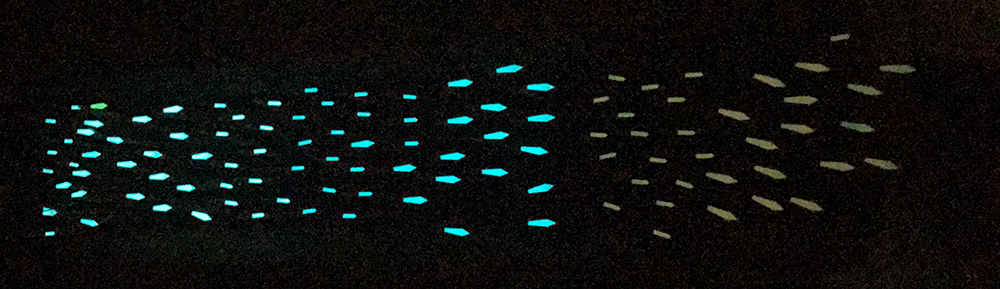

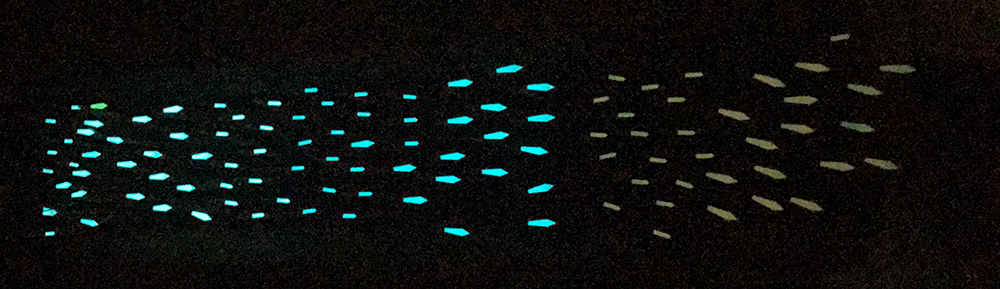

Star Wars? Nein, unsere gefüllten Zeiger in der Dunkelheit :)

Nachdem wir alle Hürden genommen hatten, war der Moment, an dem wir unsere erste eigene Uhr, die Melanocetus, in den Händen hielten, ein magischer Moment. Unzählbare Arbeitsstunden, Blut und Schweiß waren vergessen, als der Sekundenzeiger langsam auf dem Zifferblatt lief und unser Baby zum Leben erweckte.

Aber eines wussten wir natürlich noch nicht! Wie würden denn all die Käufer reagieren, die nun zum ersten Mal ihre Uhr sehen würden? Was wäre, wenn die Uhr vielen nicht gefällt, wenn plötzlich jede Menge Rücktritte auf uns einprasseln würden? Ein gespanntes Warten nach dem Versand der ersten Uhren stand uns also bevor. Wir beteten, dass die Uhren unseren Kunden mindestens genauso gefallen würden wie uns. Mit einem gewissen Rücklauf hatten wir natürlich kalkulatorisch gerechnet und zum Ende hin sind es fast 100 Vorbestellungen gewesen.

100 Uhren mit Sorgfalt zu bauen, für ein Zwei-Mann-Team, war schon nicht ohne! Trotzdem gingen Ende 2017 fast täglich 5-10 Uhren auf die Reise. Dann kamen die ersten Reaktionen und was soll ich sagen, sie waren absolut überschwänglich, ein Wahnsinn. Wir wurden mit Lob überschüttet, man konnte es kaum glauben. Von allen Vorbestellungen ist am Ende KEIN EINZIGER Käufer zurückgetreten. Ich veröffentlichte die Bewertungen nach und nach auf der Corazón del Mar-Webseite. Später konnte man direkt über unser Shopsystem bewerten und bis heute ist keine einzige Bewertung unter 5 Sternen eingegangen. Das ist für uns schon fast surreal und so sehr, wie unsere Kunden die Uhr loben und so ausführlich, wie sie ihre Bewertungen schreiben, habe ich Angst, dass man meinen könnte, wir würden diese Bewertungen selbst schreiben. Aber ich versichere hiermit hoch und heilig, keine einzige Bewertung ist von uns selbst verfasst worden, es sind 100 % alles echte Kundenbewertungen von echten Käufern!